Shrinkage occurs as molten plastic cools and contracts; warpage results when shrinkage is uneven across a part. These issues are among the most common and costly defects in injection molding, leading to dimensional inaccuracy, assembly problems, and scrap. This guide explains the root causes of shrinkage and warpage, and outlines solutions, including simulation tools like Moldex3D to predict and prevent them.

Material Effects

- Amorphous resins (ABS, PC, PS): Shrink less overall (0.4–0.7%) and more uniformly.

- Semi-crystalline resins (PP, POM, PA): Shrink more (1.0–2.5%) and tend to warp due to anisotropic crystallization.

- Glass-filled resins (PA66+GF30, PP+GF30): Shrink less in flow direction but more across flow, causing distortion if cooling is uneven.

- High-performance resins (PEEK, PPS, Torlon): Require high mold temps and careful venting; shrinkage control is critical due to cost.

Design Factors

- Non-uniform wall thickness drives differential cooling and warpage.

- Improper rib-to-wall ratios cause sinks and uneven shrinkage.

- Gate placement and orientation affect fiber alignment and shrink patterns.

- Sharp corners concentrate stress, making parts more prone to distortion.

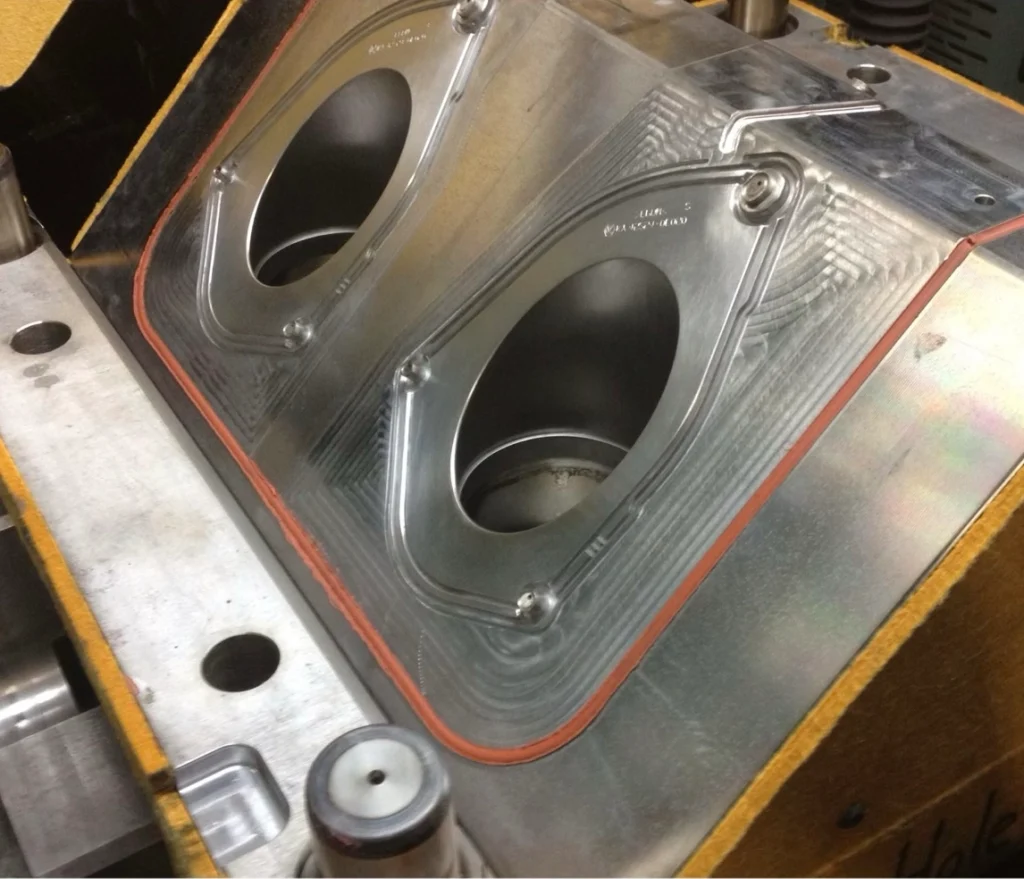

Tooling & Processing Factors

- Unbalanced cooling circuits create hot spots and uneven shrinkage.

- Insufficient packing pressure or short pack time leads to voids and shrink.

- Mold steel conductivity (H13 vs. copper alloy inserts) affects cooling uniformity.

- Ejection too early causes warpage as the part cools outside the mold.

Using Simulation (Moldex3D)

Modern CAE tools like Moldex3D can predict shrinkage, warpage, and fiber orientation in molded parts. By simulating mold filling, packing, cooling, and warpage, engineers can identify problem areas before steel is cut. Brown Tool & Mold offers Moldex3D simulation services to help reduce trial-and-error iterations, optimize cooling circuits, and achieve accurate part geometry from the start.

Prevention Tips

- Design with uniform wall thickness and core out thick sections.

- Balance cooling circuits and use high-conductivity inserts near hot spots.

- Optimize gate type and location to control flow and shrink patterns.

- Work with your molder to fine-tune packing profile and cooling time.

- Consider Moldex3D simulation for critical parts where dimensional accuracy is vital.

Case Example

A customer molding a glass-filled nylon housing experienced severe warpage due to uneven cooling and fiber orientation. By simulating the mold in Moldex3D, our engineers identified hot spots and adjusted cooling circuits, reducing warpage by over 40% and bringing the part within tolerance.

5 Key Takeaways

- Amorphous vs. semi-crystalline resins shrink differently; design accordingly.

- Wall thickness uniformity is the most powerful weapon against warpage.

- Cooling design must be balanced to prevent hot spots.

- Moldex3D simulation predicts shrink/warp before steel is cut.

- Collaborate with moldmakers early to prevent costly rework.