Introduction

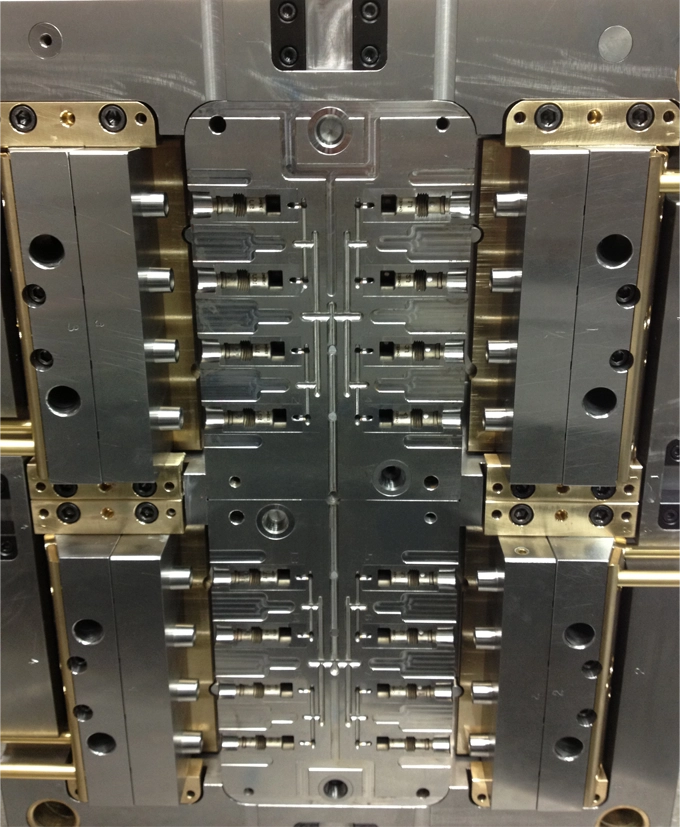

In injection mold manufacturing, surface finish is more than just appearance — it directly affects part performance, durability, and production efficiency. To create consistency across the industry, the Plastics Industry Association (formerly SPI) developed a classification system for injection mold surface finishes.

At Brown Tool & Mold, we use these SPI standards to ensure every mold meets exacting customer requirements, whether for medical devices, automotive parts, or consumer products.

What Are SPI Surface Finish Standards?

SPI surface finish standards classify mold surfaces from mirror-polished to coarse-textured. These standard grades help engineers, buyers, and toolmakers communicate finish requirements clearly, avoiding ambiguity in quotes and build notes.

SPI Finish Grades (Overview)

- Grade A (Diamond Buff Polishes): Achieved with diamond buffing compounds; mirror-like, ultra-smooth surfaces for optics and high-cosmetic parts.

- Grade B (Paper Polishes): Finished using fine abrasive papers; semi-gloss appearance for consumer and general-purpose parts.

- Grade C (Stone Finishes): Finished with oil stones; matte/satin surfaces for functional parts where gloss is not required.

- Grade D (Grit/Bead Blasting): Created via dry blasting with media; uniform textured surfaces for grip, glare reduction, or aesthetic effects.

SPI Surface Finish Chart

| Grade | Tool Process | Resulting Finish | Common Applications |

| A-1 | Diamond buff with 1 µm paste | Mirror polish | Optical lenses, clear covers |

| A-2 | Diamond buff with 3 µm paste | High gloss | Medical, cosmetic parts |

| A-3 | Diamond buff with 6 µm paste | Gloss polish | High-visibility consumer products |

| B-1 | 600 grit sandpaper | Semi-gloss | Consumer parts, electronics |

| B-2 | 400 grit sandpaper | Fine matte | Packaging components |

| B-3 | 320 grit sandpaper | Matte | Automotive interiors |

| C-1 | 600 grit stone | Smooth matte | Industrial parts |

| C-2 | 400 grit stone | Medium matte | Tooling, functional parts |

| C-3 | 320 grit stone | Rough matte | Heavy-duty products |

| D-1 | Dry blast #240 oxides | Fine blast texture | Handles, grips |

| D-2 | Dry blast #240 glass beads | Medium texture | Automotive trim |

| D-3 | Dry blast #24 aluminum oxide | Coarse texture | Non-slip surfaces |

Why Surface Finish Matters

- Part appearance: high-cosmetic parts need high-polish finishes, while industrial parts often prefer matte.

- Functionality: texture can add grip, reduce glare, or improve adhesion for paint/printing.

- Cycle time: smoother finishes can reduce ejection resistance and speed production.

- Durability: appropriate finishes reduce wear and can extend mold life.

How Brown Tool & Mold Applies SPI Standards

- Match finish to function: From textured grips to A-1 optical polishes, we recommend finishes that serve performance and cost.

• Integrate finish into DFM: We align gate/parting line/venting and polishing strategy to your cosmetic zones.

• Precision execution: Skilled polishers and controlled processes ensure finishes meet or exceed spec across cavities.

Conclusion & Call to Action

The SPI surface finish standard ensures clarity between customers and mold makers, helping manufacturers avoid costly misunderstandings. Whether you need a mirror-polished medical tool or a textured automotive mold, Brown Tool & Mold delivers precision finishes that meet or exceed SPI specifications.

👉 Request a Quote or speak with an engineer about your surface finish requirements:

Links

- Plastics Industry Association (SPI): plasticsindustry.org

- Injection Mold Design Services: browntoolandmold.com/injection-mold-design

- Mold Manufacturing: browntoolandmold.com/mold-manufacturing

- Contact Brown Tool & Mold: browntoolandmold.com/contact